A reliable measurement of materials’ surface energy

Surface tension, surface energy and wettability: what are the test inks made for?

" Surface tension " generally applies to liquids – this is the amount of force per length unit that applies on a liquid surface in balance with the external environment.

" Surface tension " generally applies to liquids – this is the amount of force per length unit that applies on a liquid surface in balance with the external environment.

For solids – which atoms have a limited mobility – the term “surface tension” becomes "surface energy".

Whether we are dealing with a liquid or a solid matter, both surface energy and surface tensions are measured in mN/m, dyn/cm or mJ/m².

Whereas surface energy and surface tension refer to a notion of quantity, wettability refers to the material’s quality. “The wettability is the ability of a material surface to be let wet by liquids; or the capacity for a solid substance to accept a liquid while letting said liquid to spread as widely as possible on its surface” (Rama 1973).

Whereas surface energy and surface tension refer to a notion of quantity, wettability refers to the material’s quality. “The wettability is the ability of a material surface to be let wet by liquids; or the capacity for a solid substance to accept a liquid while letting said liquid to spread as widely as possible on its surface” (Rama 1973).

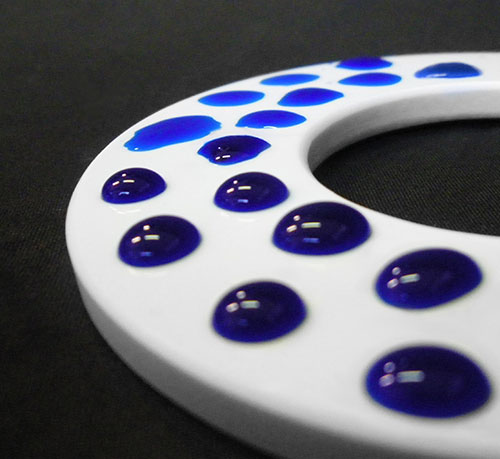

The more important the surface energy is, the more important wettability. When a liquid can completely spread over a solid surface, the liquid is said to wet, or wetting is complete: wettability can be considered as very important.

Test inks help in determining the surface energy of any material, using surface tension of a liquid when applied onto. Once the material surface energy is known, its degree of wettability can be determined.

Why measuring the material’s surface energy?

Using test inks to measure the material’s surface energy can help:

- Assess the effectiveness of a corona or plasma treatment

- Control that a degreasing or cleaning operation has been performed efficiently

- Check that a material is clean enough (or its properties are sufficient) to allow bonding with ink or glue

- Perform quality control on materials upon receiving a shipment

- Check whether a surface treatment has already been applied to a surface.

Test inks and measuring the material surface energy: DIY

AcXys Technologies has released reliable test inks that can measure the material’s surface energy – this surface energy is close to superficial ink tension.

How to:

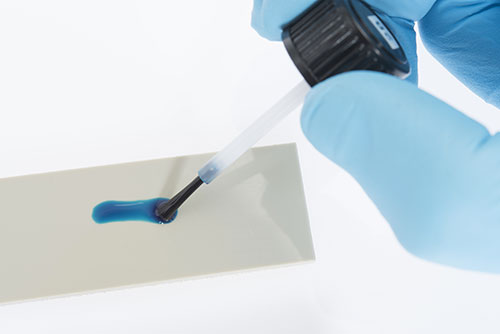

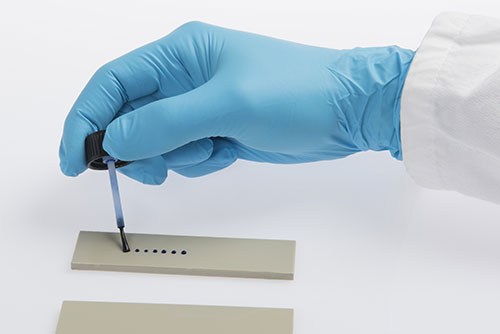

- First apply the ink on the surface to test using the ink pen, a brush (depending on the ink container) or a cotton bud if the surface is not clean.To determine which value to assess first, please read our FAQ.

- If the test ink “wets” the surface for 2 seconds at least – the ink continuously spreads over the surface – the solid surface energy is greater than the ink surface tension value. In that case, an ink with a greater tension value should be used.

- If the ink “unwets” (ink shrinks on the surface in less than 2 seconds), the solid surface energy is inferior to ink surface tension. In that case, an ink with a lower tension value should be used.

When the ink drop remains on the surface for 2 seconds without shrinking or further spreading – bingo! The material’s surface energy value matches the highest ink value!

Should you have further questions, please check our FAQ. They are here to help!

Otherwise, look at the ink types.